Features

1. Chinangwa chaicho

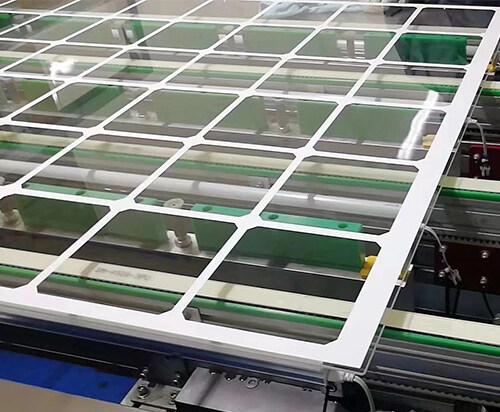

Inonyanya kushandiswa pakushongedza ribhoni ye solar photovoltaic modules.

2. Yakanakisa strain kugadzirisa

Nekugadzirisa mhando kana chikamu cheyakadzika, yepakati uye yakakwira yekubikira poindi zvinonyungudutsa mufomula, inogona kuchengetedza yakanakisa chiitiko mukati meiyo solder tembiricha hwindo.

3, High goho mwero

Iyo synergy yeakasiyana-siyana ekupinda uye ekunyorovesa maajenti anoderedza kushushikana kwepasi pakati pechifukidzo uye ribhoni rekutengesa, kuderedza mwero wemanyepo wekutengesa uye chipping rate.

4, Hapana kuchenesa kunodiwa mushure mekunama

Yakaderera yakasimba yemukati, iyo mhangura yemhangura yakachena mushure mekutsvaira, ine mafuta mashoma, makristasi uye mamwe masara, uye hapana kuchenesa kunodiwa.

5, Kuchengetedza kwakanaka uye kuchengetedzwa kwezvakatipoteredza

Teerera neRoHS uye REACH zviyero, uye sangana neInternational Electro technical Commission IEC 61249-2-21 halogen-yemahara mwero.

Performance parameters

| Item | Tsanangudzo | Reference standards |

| Copper mirror experiment | Pass | IPC-TM-650 2.3.32 |

| Refractometer concentration (%) | 27-27.5 | Lichen yakakwirira-chaiyo refractometer (0-50) |

| Welding diffusivity | ≥85% | IPC/J-STD-005 |

| urface insulation resistance | > 1.0 × 108ohms | J-STD-004 |

| Mvura inobvisa resistivity | Kupfuura: 5.0 × 104ohm·cm | JIS Z3197-99 |

| Halogen content | ≤0.1% | JIS Z3197-99 |

| Silver Chromate Test | Rudzi rwebepa rekuyedza chena kana mwenje yero (halogen-isina) | J-STD-004;IPC-TM-650 |

| Fluorine yemukati bvunzo | Pass | J-STD-004;IPC-TM-650 |

| Flux giredhi | OR/M0 | J-STD-004A |

| Halogen-yemahara mwero | Conform | IEC 61249 |

Applications

Ichi chigadzirwa chinowanzoenderana neP-mhando uye N-mhando yebhatiri zvikamu;2. Ichi chigadzirwa chakakodzera mhando dzese dzetambo welding michina.

Mirayiridzo

1, Ichi chigadzirwa chinoshandiswa zvakanyanya mumichina yekurumbira tambo senge Siemens uye Mavericks parizvino pamusika.

2, Inoshandiswa mune optoelectronics uye photovoltaic maindasitiri kutsiva inogona corrosive activated rosin-ine fluxes uye mamwe rosin-based fluxes.Inokodzera welding tinned solder strips, isina mhangura uye mapuranga edunhu pasina pre-coating.

3, Yakakodzera otomatiki welding yemasero ezuva akaputirwa nekunyudzwa kana kupfapfaidza.Iyo ine yakakwirira welding kuvimbika uye yakanyanya kuderera yenhema welding rate.

Process control

1, Izvo zvinoshanda zvinongedzo zve flux zvinogona kudzorwa nekudzora chaiyo giravhiti yekuyerera.Kana iyo chaiyo giravhiti inodarika kukosha kwakajairika, wedzera diluent munguva kuti udzorere chikamu chakaiswa;kana iyo chaiyo giravhiti yakadzikira pane yakajairwa, dzosera iyo yakatarwa chikamu nekuwedzera flux stock solution.

2, Kana iyo welding tambo yanyanya oxidized kana tembiricha yekushanda yakadzikira, nguva yekunyura kana huwandu hwekuyerera hwakaiswa hunofanira kuwedzerwa kuti ive nechokwadi chekuita welding (maparamita chaiwo anotemerwa kuburikidza nediki batch kuyedza murabhoritari).

3, Kana iyo flux isingashandiswe kwenguva yakareba, inofanirwa kuchengetwa mumudziyo wakavharwa kuti uderedze kuvhurika kana kusvibiswa.

Zvekungwaririra

1, Ichi chigadzirwa chinogona kupfuta.Paunenge uchichengeta, chengetedza kubva kune moto uye chengetedza maziso ako neganda.

2, Munzvimbo yebasa, kana imwe welding ichiitwa panguva imwe chete, mudziyo wekuburitsa mweya unofanirwa kushandiswa kubvisa zvinhu zvinoputika mumhepo uye kuderedza njodzi dzehutano hwebasa.

3, Iyo inoyerera mushure mekuvhurwa inofanira kuiswa chisimbiso kutanga yozochengetwa.Usadurure iyo yakashandiswa flux kumashure kwekutanga kurongedza kuti uve nechokwadi chekuchena kwemhinduro yekutanga.

4, Ndokumbira uverenge Material Chengetedzo Data Sheet nekungwarira usati washandisa chigadzirwa ichi.

5, Usakanda kana kurasa chigadzirwa ichi zvakasununguka.Zvigadzirwa zvekupedzisira-zvehupenyu zvinofanirwa kupihwa kune imwe nyanzvi yekuchengetedza nharaunda kuti zviraswe.