Nhanganyaya

Ichi chigadzirwa imvura yakachena yemukaka inowanikwa nekuita hollow silica nanoparticles nemapoka anoshanda ane organic matter.Iyo yakaputirwa pamusoro pegirazi pamusoro peiyo roller coating process, uye mushure mepakati tembiricha kurapa uye yakanyanya tembiricha sintering, iyo organic zvinhu inopiswa zvachose, iyo nanoparticles ichave yakanyatso kusanganiswa pamwe chete uye ichivimba neakagomba chimiro chesilica nanoparticles. gadzira yakaderera refractive index yefirimu layer.

Parameters

| Item | Standard Parameters | Test Conditions |

| Chitarisiko | 乳白色 chena mukaka | Kuongorora Kwekuona |

| pH kukosha | 4±1 | pH Indicator |

| Relative Density (g/ml) | 0.82±0.05 | chaiyo giravhiti nzira |

| Solid content (%) | 3.0±0.4 | 120 ℃, maawa maviri |

| viscosity (cps) | 2.0±0.5 | 25℃ |

Performance zviratidzo

Chitarisiko

mukaka chena mvura

Transmittance

Transmittance yakawedzera neinopfuura 2.3% pahwaro hwegirazi-chena girazi, mukati meiyo Broadband wavelength renji ye400-1100nm (inoyerwa nekushandisa iyo Beijing Taibo GST mhepo-inoyangarara desktop desktop yakatevedzana transmittance testers).

Kuvimbika Indekisi

| Items | Maitiro | Frame of Reference | Results | Notes |

| kupisa kwakanyanya uye humidity | 1000 maawa | JC/T 2170-2013 | Kudzikisira <1% | Kutevedzera mitemo yeindasitiri |

| Salt spray test | 96 maawa | JC/T 2170-2013 | T attenuation <1% | Kutevedzera mitemo yeindasitiri |

| Wet freezing test | 10 kutenderera | JC/T 2170-2013 | T attenuation <1% | Kutevedzera mitemo yeindasitiri |

| Thermal cycling test | 200 kutenderera | JC/T 2170-2013 | T attenuation <1% | Kutevedzera mitemo yeindasitiri |

| UV bvunzo | Yakaunganidzirwa 15kw.h/m2 Total radiation panguva | JC/T 2170-2013 | T attenuation <0.8 | Kutevedzera mitemo yeindasitiri |

| PCT Yakawedzera Kuchembera Muedzo | 48 maawa | JC/T 2170-2013 | T attenuation <0.8 | Kutevedzera mitemo yeindasitiri |

| Kuoma kwepenzura | ≥3H | JC/T 2170-2013 | Hapana mavanga anooneka | |

| Acid resistance | 24 maawa | JC/T 2170-2013 | T attenuation <0.8 | Kutevedzera mitemo yeindasitiri |

| Adhesion Test | Muchinjikwa-cheka bvunzo | JC/T 2170-2013 | giredhi 0 | |

Process Zvinodiwa

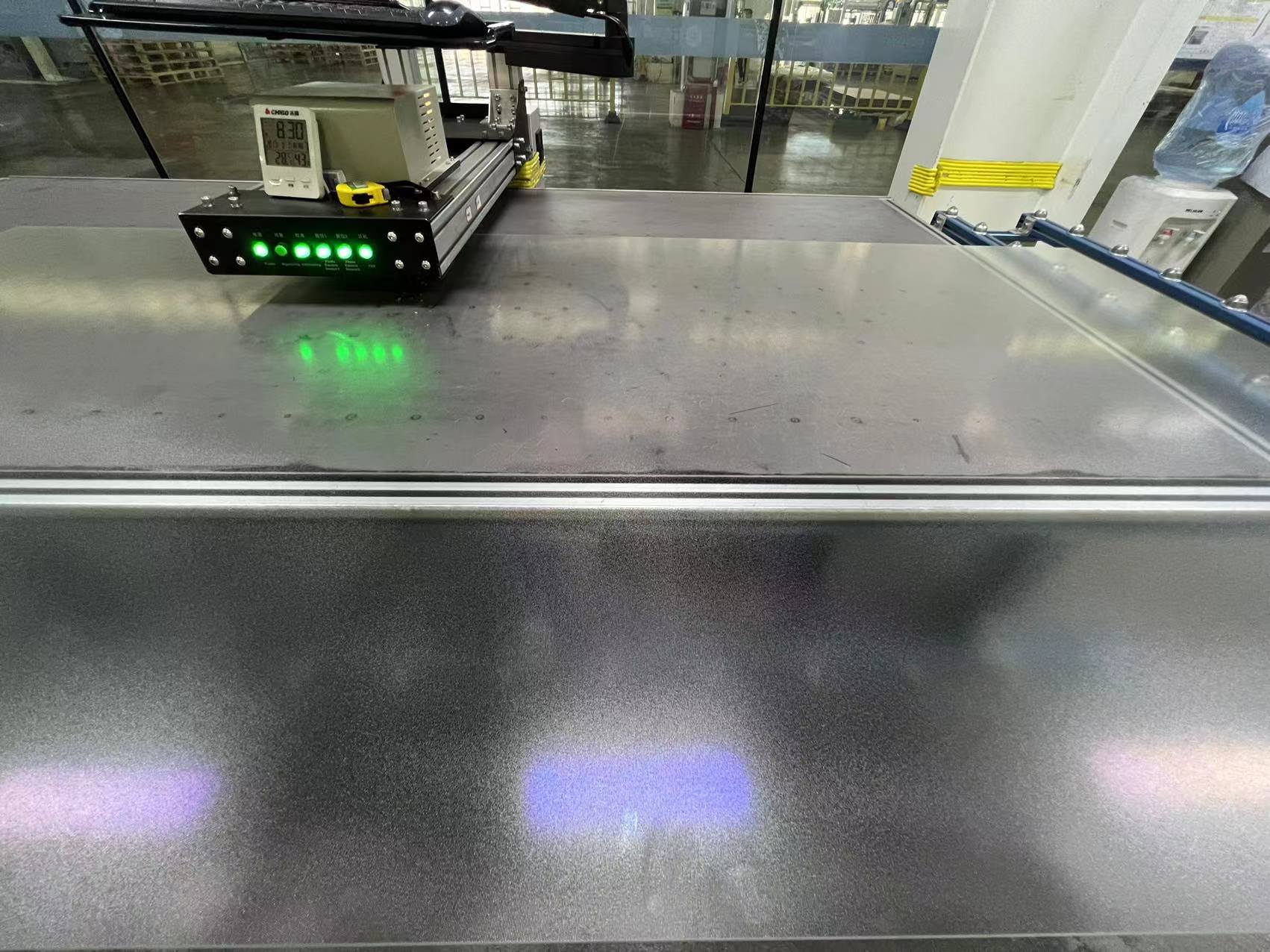

Mushonga wekuputira unoshandiswa uchishandisa roll coating process.

Coating rollers inofanira kushandisa PU rollers, kuoma kunofanira kuva 35 madhigirii -38 madhigirii zvakakodzera, coating quantitative roller inokurudzirwa kushandisa 80-100 mesh.

Kupfeka tembiricha yefirimu 20-25 degrees.

Coating film humidity ≤ 45 degrees (high humidity board surface iri nyore kuve isina kuenzana).

Diluent: Isopropyl Doro (chidimbu chekuvhara) kana anhydrous ethanol.

Roller kudhinda nzira dzekubvisa: rubber roller lap isina guruva jira kana chamois jira.

Kana iyo firimu yakaumbwa, kana hunyoro hwekamuri yekuputira hwakanyanya kana girazi repamusoro risina kuomeswa nemhepo, iyo firimu pamusoro inozove nyore atomised mushure mekunge firimu raumbwa uye mwero wekufambisa kwechiedza uchaderedzwa.

Zvekungwaririra

Iyo yekuputira mhinduro ndeye solvent-based (doro) nanosol system uye haina chepfu.Nekuda kwekusagadzikana kwakasimba kweanhydrous ethanol iri mumhinduro, magirovhosi uye masikisi anofanirwa kupfekwa panguva yekushandiswa uye nguva dzose mweya mutsva unofanirwa kushandiswa kudzivirira kubata kufema kana kufemerwa zvakanyanya zvichikonzera ganda rakaoma nehuro uye kusagadzikana kweziso.

chigadzirwa chinofanira kuchengetwa pa 25 madhigirii centigrade pazasi, anogona kuchengetedzwa kwemwedzi 3, chengetedzo muitiro anofanira kudziviswa kusangana nemoto uye simba chiedza sosi rakananga zuva, kuitira kuti kusakonzera moto kana kudziyisa mhinduro kukwegura.